The difference hardness between the grinding wheel and the abrasive

2019-04-22 reading

The hardness of the grinding disc refers to the difficulty of the abrasive grains on the surface of the grinding disc falling off under the action of grinding force.The hardness of the grinding disc is soft, which means that the abrasive grains of the grinding disc are easy to fall off, and the hardness of the grinding disc is hard, indicating that the abrasive grains are difficult to fall off. (Important! The hardness of the grinding disc does not refer to the hardness of the grinding disc )

The hardness of the grinding disc and the hardness of the abrasive are two different concepts. The same kind of abrasive can be made into grinding disc of different hardness, which is mainly determined by the performance and quantity of the bonding agent and the manufacturing process of the grinding disc . Significant differences in the grinding disc and the cutting is "self-sharpening", select the hardness of the abrasive disc, in fact, choose sand is not self-sharpening disc, hoping also sharp abrasive particles do not fall off too early, and do not blunt the Fall off.

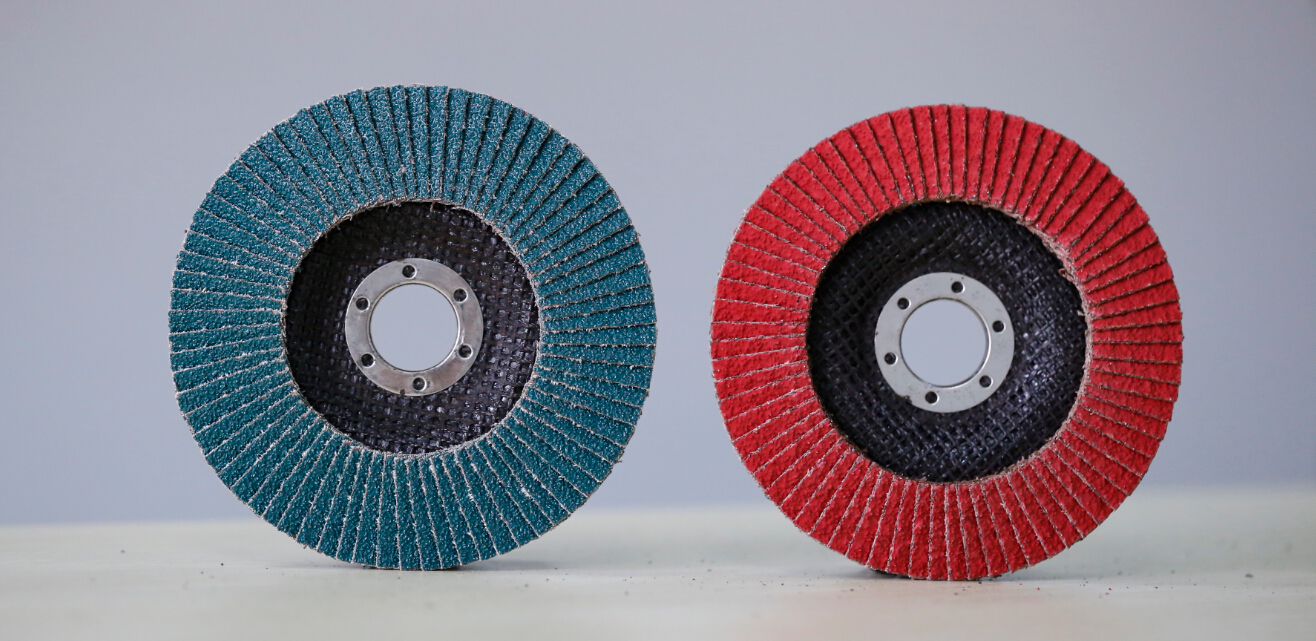

flap disc manufacturer,grinding wheel factory,abrasive blet supplier

The general principle for selecting the hardness of the grindingdisc is to use a hard grinding disc in order to prevent the abrasive from falling off prematurelywhen processing the soft metal . When processing hard metals , in order to timely remove the blunt abrasive particles to expose new abrasive grains with sharp edges (ie, self-sharpness), a soft grinding disc is used. The former is because when grinding soft materials, the working abrasive grains of the grinding disc wear very slowly, and do not need to be detached too early; the latter is because when grinding hard materials, the working abrasive grains of the grinding disc wear faster and need to be faster. Update.

flap disc manufacturer,grinding wheel factory,abrasive blet supplier

In the case of fine grinding, in order to ensure the grinding accuracy and roughness , a slightly harder wheel should be used . When the workpiece material has poor thermal conductivity and is prone to burns and cracks (such as grinding hardalloys ), the selected grinding wheel should be softer .

Grinding disc hardness grading and code

| Hardness level | Code | |

| Big class | Small level | |

| so soft | so soft | D. E. F. |

| soft | Soft 1 | G |

| Soft 2 | H | |

| Soft 3 | J | |

| Medium soft | Soft 1 | K |

| Soft 2 | L | |

| in | Medium 1 | M |

| Medium 2 | N | |

| Medium hard | Medium hard 1 | P |

| Medium hard 2 | Q | |

| Medium hard 3 | R | |

| hard | Hard 1 | S |

| Hard 2 | T | |

| Super hard | Super hard | Y |