Different grinding wheel hardness for different processing materials

2019-10-31 reading

Different grinding wheel hardness for different processing materials

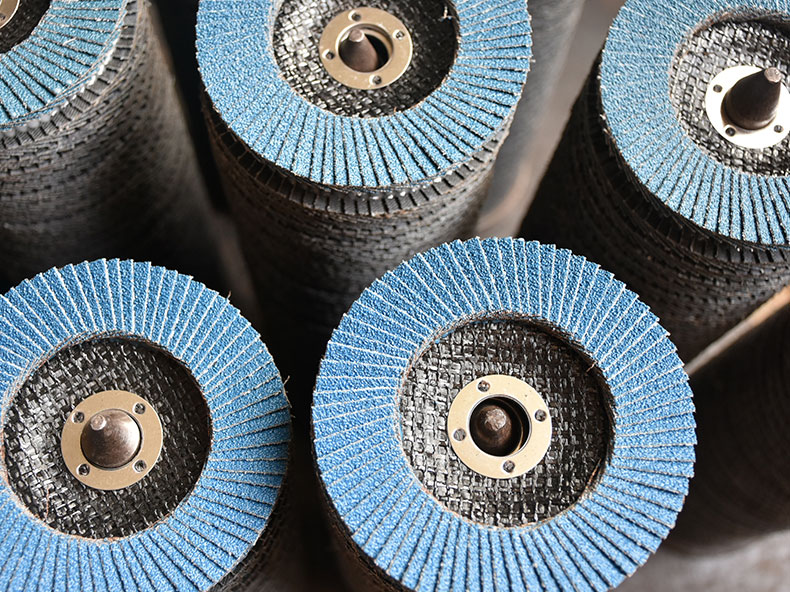

We know that the grinding wheel is a circular fixed abrasive with a through hole in the center made of abrasive and bonding agent. Its characteristics are determined by factors such as abrasive, particle size, hardness, bonding agent, shape and size, depending on the hardness and The bonding agent can obtain grinding wheels of different materials, which are applied to the processing of materials in different industries. One important parameter is the hardness of the grinding wheel. In actual production, the hardness of the grinding wheel used for different processing objects is also different.

grinding wheel,flap disc manufacturer,flap wheel factory,zirconia abrasive belt

In ordinary processing, the thermal conductivity of some workpiece materials is poor, generally grinding with a slightly softer grinding wheel; in the process of fine grinding, in order to ensure the grinding precision and roughness, a slightly hard grinding wheel should be used.

Especially in some production industries where many grinding wheels are used, the unwritten principle is: when processing soft metal, in order to prevent the abrasive from falling off prematurely, the hard grinding wheel is used; when processing the hard metal, in order to timely remove the blunt abrasive particles Use a soft grinding wheel.